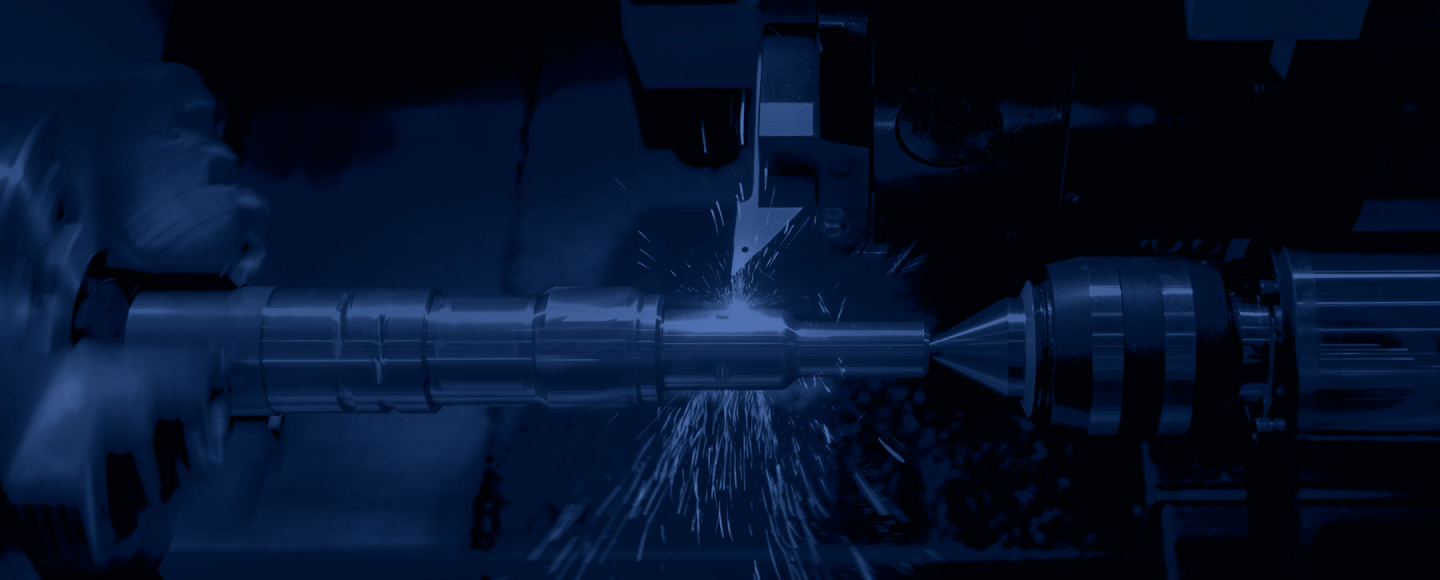

From bar stock to finished gears, Ascent has the capabilities to manufacture your gears accurately and efficiently. With versatile CNC equipment, proven high-quality gear machines, and an array of precision inspection equipment, we can maintain the total quality control our customers demand, while keeping costs competitive.

Some Machining Capabilities Include:

- Turning up to 16” diameter

- Gear-cutting up to 16” diameter and 16” face

- Gear qualities up to AGMA 14

- Broaching

- Keyseating

- Honing

- Milling

- Heat-treating and finishing

Our Inspection Equipment Includes:

- 1 S & F gear tester with “redline” tape

- 1 Parkson gear tester

- 1 GSI gear tester

- 1 ITW 1218-A “Sine-Line” lead checker w/charts

- 1 Phase II Rockwell hardness tester

- 1 Micro-Vu optical comparator

- 1000+ gage pins

- Over 50 sets of gear measuring wires

- 220+ hobs and gear shaper cutters

- 50 master gears

- Various micrometers, test indicators, and more

Specifications

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Duis et ligula odio. Proin rhoncus gravida ante, ut elementum purus rhoncus in. Vivamus tempus, tellus ut laoreet euismod, felis urna molestie erat, eget feugiat risus est eget nisl. Aliquam felis ex, placerat in rutrum sed, posuere in dui. Duis pulvinar quis massa vulputate euismod. Aenean fringilla neque quis arcu facilisis tincidunt. Sed eu eros nulla. Phasellus at accumsan diam.

Related Products

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam vel posuere nibh. Praesent pellentesque fermen tum venenatis. Aenean et accumsan libero. Vivamus et ipsum a est facilisis ornare in sit.

Lorem Ipsum Dolor

Lorem Ipsum Dolor